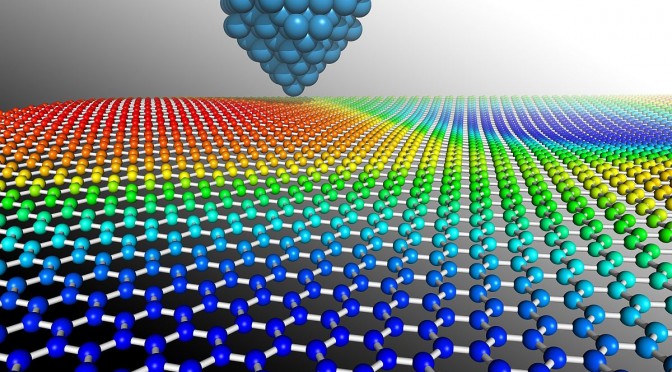

Input from tests sent to significant electric vehicle and battery makers have shown solid interest for and affirmed the predominant execution of Balama covered circular graphite for lithium (Li) particle applications. The IEA joins a 25,000 tpa Coated Spherical Graphite Facility, obliging 50,000 tpa of -100 US work graphite as food. Furthermore, 25,000 tpa of 95% aggregate graphitic carbon (TGC) recarburiser by-item will likewise be delivered as a major aspect of the spheroidisation process.

Starting capital use prerequisites will be pretty nearly US$80 million with normal yearly money working expenses of US$3,200 per ton free on board for covered circular graphite (barring recarburiser by-item credits). A Chief Technology Advisor has likewise been designated to help Syrah with actualizing its covered circular graphite methodology.

In light of talks with potential clients, covered circular graphite right now offers for between US$7,000 to US$10,000 per ton. Syrah accepts, through exchanges with real battery makers, that a huge increment in the worldwide interest for lithium particle batteries is quickly drawing closer with electric vehicles and battery stockpiling getting through to the standard. This is relied upon to shape another period of interest in certain basic minerals, with graphite at the front line. Starting test work has demonstrated that anodes produced using Balama covered round graphite are better than Chinese normal graphite anodes and a main engineered graphite anode.

A noteworthy anode maker has estimate circular graphite interest to increment at a compound yearly development rate of 26% from 2014 to 2020, to achieve 133,000 tons for each annum by 2020. To fulfill this foreseen increment sought after for Li-particle batteries, a few noteworthy partnerships have started or declared arrangements to build "giga" or "uber" Li-particle battery industrial facilities over the course of the following 5 years. Benchmark Minerals estimates that worldwide Li-particle battery limit will triple by 2020 to achieve 120 GWh, in view of arranged generation by LG Chem, Tesla, Foxconn, BYD Auto and Boston Power.

At present, just -100 US work and littler graphite is utilized to create circular graphite. In light of the drop size appropriation profile of existing graphite mines, an extra 6 to 9 new mines creating the obliged size part will be required by 2020.

Syrah accepts that the metallurgical and creation profile of the Balama Project positions Syrah to be a main maker of round graphite for Li-particle battery applications because of its prevalent execution attributes. More than 40 years of Ore Reserves additionally gives certainty to driving significant battery makers that the Balama Project will empower Syrah's proposed Coated Spherical Graphite Facility to turn into a long haul, reasonable supplier.

Reference:

http://www.businesswire.com/news/home/20150617006542/en#.VYJVlfmqqko

Starting capital use prerequisites will be pretty nearly US$80 million with normal yearly money working expenses of US$3,200 per ton free on board for covered circular graphite (barring recarburiser by-item credits). A Chief Technology Advisor has likewise been designated to help Syrah with actualizing its covered circular graphite methodology.

In light of talks with potential clients, covered circular graphite right now offers for between US$7,000 to US$10,000 per ton. Syrah accepts, through exchanges with real battery makers, that a huge increment in the worldwide interest for lithium particle batteries is quickly drawing closer with electric vehicles and battery stockpiling getting through to the standard. This is relied upon to shape another period of interest in certain basic minerals, with graphite at the front line. Starting test work has demonstrated that anodes produced using Balama covered round graphite are better than Chinese normal graphite anodes and a main engineered graphite anode.

A noteworthy anode maker has estimate circular graphite interest to increment at a compound yearly development rate of 26% from 2014 to 2020, to achieve 133,000 tons for each annum by 2020. To fulfill this foreseen increment sought after for Li-particle batteries, a few noteworthy partnerships have started or declared arrangements to build "giga" or "uber" Li-particle battery industrial facilities over the course of the following 5 years. Benchmark Minerals estimates that worldwide Li-particle battery limit will triple by 2020 to achieve 120 GWh, in view of arranged generation by LG Chem, Tesla, Foxconn, BYD Auto and Boston Power.

At present, just -100 US work and littler graphite is utilized to create circular graphite. In light of the drop size appropriation profile of existing graphite mines, an extra 6 to 9 new mines creating the obliged size part will be required by 2020.

Syrah accepts that the metallurgical and creation profile of the Balama Project positions Syrah to be a main maker of round graphite for Li-particle battery applications because of its prevalent execution attributes. More than 40 years of Ore Reserves additionally gives certainty to driving significant battery makers that the Balama Project will empower Syrah's proposed Coated Spherical Graphite Facility to turn into a long haul, reasonable supplier.

Reference:

http://www.businesswire.com/news/home/20150617006542/en#.VYJVlfmqqko